-

ONE THIRD OF SOW FARMERS OPT FOR A MOVABLE FLOOR

-

80% REDUCTION OF PIGLET LOSSES DUE TO CRUSHING BY THE SOW

-

(1): $350 investment recovered within three years, or: (2): PAYBACK PERIOD OF THREE YEARS

The movable floor provides a quick return of investment

The percentage of piglet lay-ons can be reduced by about 80% with an additional investment in a movable floor of $300 to $400 per farrowing crate. This additional investment is recovered quickly.

Piglet mortality is undesirable from both the economical and the animal welfare perspective. High levels of piglet mortality also lead to lower job-satisfaction. Piglet mortality can be reduced by creating a healthy climate in the barn, and by focusing on sow and piglets during and after the birth process. 40% to 50% of piglet mortality in the first week after birth is caused by crushing. The farrowing crate layout is the largest contributor to the percentage of crushed piglets.

A moveable floor, where the sow’s lying area rises when the sow stands up, prevents piglets from moving around under the sow when she lies down again. This can save up to 85% of the piglets, which equates to seven piglets per farrowing crate per year.

The movable floor has not stood still in its development over the last twenty years. In the first versions of balance sow lift floors, the piglets went up and down. That setup had two drawbacks. If the compressed air supply fails, the piglets go down and cannot reach the sow’s teats to drink. In addition, lifting the piglets has constructional consequences. The construction of the superstructure on the floor must exactly match the size of the farrowing crate. Deviations in the dimensions present major challenges for the installation of such floors.

With the current movable floors, only the sow section rises about 10 inches. When the sow stands up, she pushes up a switch that raises the floor by means of air cylinders. When the sow lies down, the switch is released again and the sow area drops down so the piglets can drink again. In case of a loss of air pressure, the sow section will not raise up and the floor basically turns into a regular farrowing crate. The piglets can then still drink from the sow. Crushing of the newborn piglets is prevented by the fact that the piglets cannot climb onto the elevated sow section. The area under the sow is then piglet-free when she lies down again.

The more piglets, the better the results

The more potential crushed piglets, the higher the potential return on investment from the movable floor. “There are more and more piglets per sow, and, as a result, the farrowing crates are getting fuller, which also increases the chance of piglets getting crushed by the sow,” says Jan Pijnenburg of DLV Advies. He points out that in a larger farrowing crate the piglets can lie more evenly distributed throughout the crate and therefore have less chance of getting crushed under the sow.

The combination of a moveable floor and a larger farrowing crate is also an option, but a more expensive one. The DLV expert estimates the additional investment to be around €700 per farrowing sow. Of this, roughly €300 to €400 is for a moveable floor and another €300 for an extra square meter of farrowing pen. “With the current earnings model, that doesn’t make financial sense,” says Pijnenburg. “If you go one step further, such as free-range stall pens, the higher investment is only justified in a concept where a premium on the price can be given.”

A free-range farrowing floor does provide more space for the sow and piglets, but managing piglet mortality is still a challenge in this regard. “The larger farms with more than 1,000 sows at multiple locations mainly choose simple, proven systems that are easy to operate and require little maintenance,” Pijnenburg says. He sees that a moveable floor in a traditional farrowing barn is mainly an economic consideration.

“Arno Steenbergen of farm supplier Nijenkamp confirms that, and says that about one third of sow farmers choose free-range farrowing stalls, one third choose a traditional farrowing stall and one third choose traditional farrowing pens with moveable floors.”

Entrepreneurs find the requiured investment of a farrowing pen with moveable floors often too high, but there is an increasing demand for a combination of free-farrowing stalls and balance floors, says Steenbergen.

Payback period of movable floors

Dutch sow farmers have a large choice of farrowing stalls for new or renovated installations: traditional, free-range or a farrowing pen, all with or without an adjustable floor. About one-third to one-half of the sow farmers investing today choose a traditional farrowing house with a moveable floor in the farrowing house. Especially in a free-range farrowing house where mortality can be as high as 2 to 3%, such a system can offer a solution.

A movable floor works 24/7, says Ernie Maas of flooring specialist Nooyen, who would recommend a movable floor to any pig farmer. “The additional cost of a moveable floor is about €350 per farrowing pen, and yields about seven piglets extra per floor per year,” Maas points out. With a piglet yield price of €50, €35 remains after deduction of €15 for feed, manure disposal, and veterinary costs. The payback period is then 350/(7×35)=1.4 years.

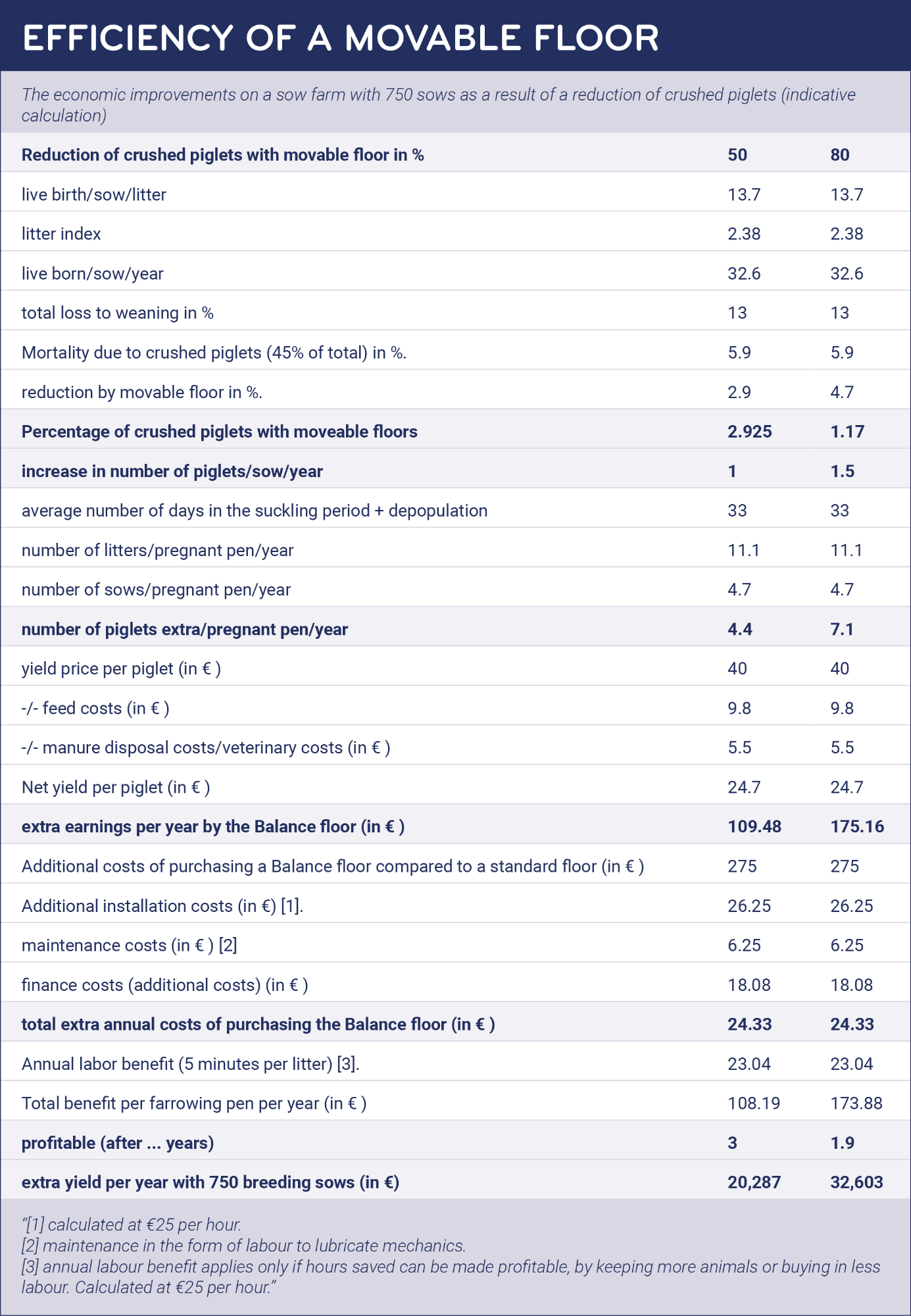

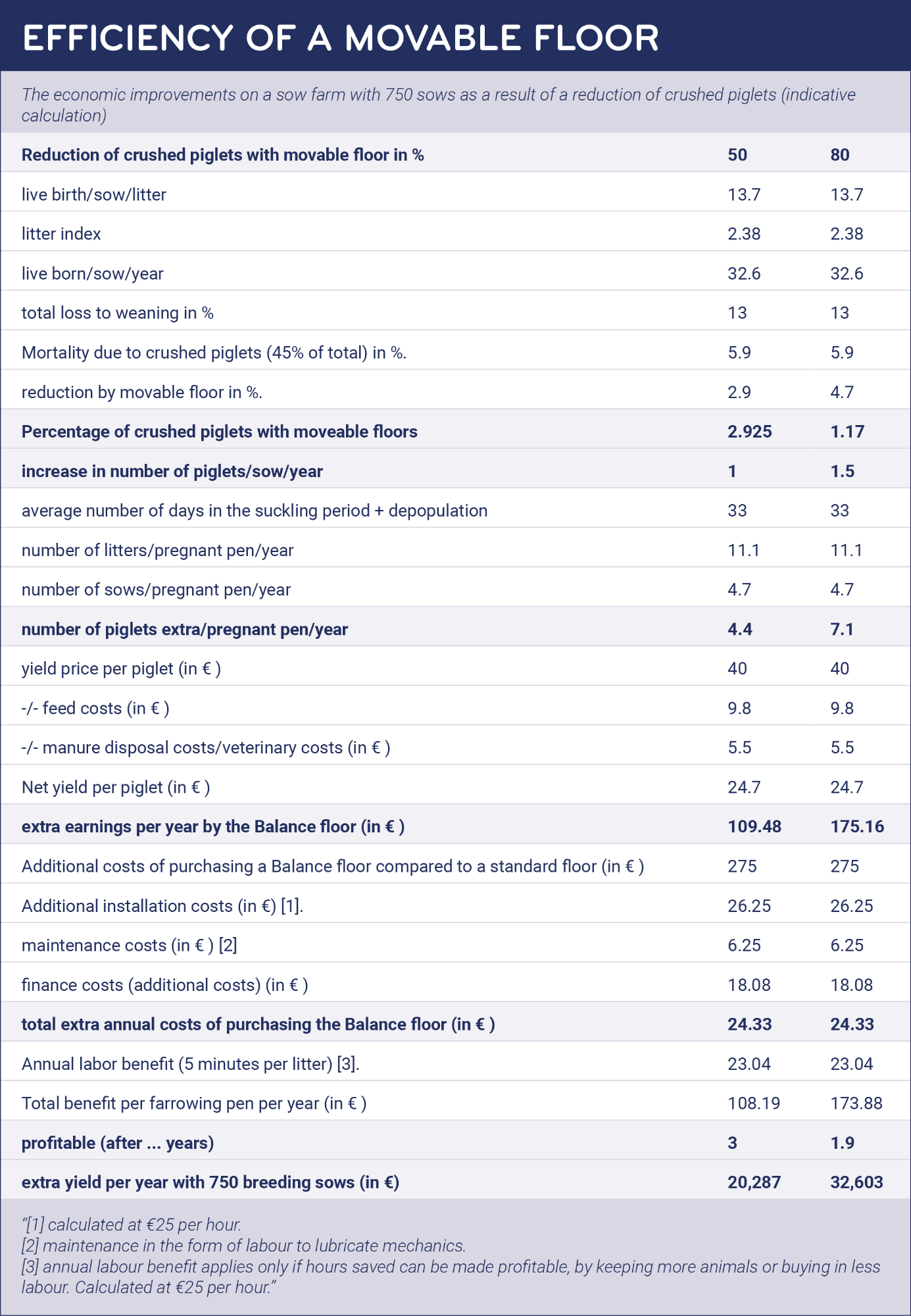

In addition to this simple calculation of the payback period, Maas also uses an extended calculation (see table), in which the various farm-specific variables can be adjusted. This economic calculation is simple to perform for every company.

Maintenance of movable floors

Pijnenburg sees few Dutch companies opting for free-range stall pens with moveable floors. This is due to economic reasons and also because each technical component requires maintenance or can cause failure. “Older Balance floors need more maintenance than new ones and that has two reasons,” Maas points out. First, the floors were built with different specifications and secondly, wear and tear can occur because the floor has moving parts.

Maintenance of the floors potentially consists of exchanging parts, such as rubbers and occasionally the cylinders. How often this should be done depends on the positioning of the frame and the cylinders. The manure pit must be deep enough and regularly draining the manure increases the lifespan of the floor.

Hooijer says that if there is a malfunction in one of the four cylinders that pushes the sow up, the sow will still go up because of the leverage construction that the Vari Plus floor has. If there is insufficient air pressure, the system will not work or will not work properly. To prevent damage to the air pipes, such as being eaten by mice and rats, pest control is very important to increase the lifespan of the floor.

Developments in movable floors

Netherlands

“The Dutch sow farmer is still hesitant to combine free-range farrowing with a movable floor. Most sow farmers now choose to invest in a traditional farrowing pen. About one third of the farmers choose for a movable floor. At Aeres College a number of free-range farrowing crates have been installed with movable floors, and an additional number of such crates will be installed in the near future.

At research farm Schothorst there will also be free-range farrowing floors installed. This so-called WellFarrowing floor will also include a weighing installation to weigh the sows in the farrowing crate.”

Germany

German sow farmers have so far invested little in balance floors. But German pig farmers are dealing with stricter legislation, under which sows must be kept in free-range stalls within fifteen years. In addition, the sows can not be in a farrowing stall in the farrowing house for more than five days.

Canada

Canada is seen as a progressive country and there is a great demand for movable floors, especially by the larger professional farms. There is no legislation yet for free-farrowing.

France

France has many integrators and of these, it is estimated that 70% to 80% are investing in a free-range stalls with a movable floor.