It is crucial for the overall production economy that the pigs are slaughtered at the weight where the most optimal economic yield is achieved. With high feed prices, the reference point for optimal slaughter weight may be pushed downwards when transfer prices have not (to the same extend) increased.

Optimal slaughter weight varies depending on economic conditions and the market situation, which is why there will also be variations between countries when looking at feed prices, transfer prices and, not least, meat percentage. Thus, optimal slaughter weight is a parameter that must be continuously monitored, as it is not a constant optimal level.

With the high feed prices, the topic is highly important right now, and an obvious opportunity to reassess your production and the situation you are in – and, of course, include it as a regular routine, also when the market situation changes. It is essential to know your own level of production, and where you are positioned in relation to the ones you may compare yourself with.

Each time the slaughter weight is increased by one kilogram, the settlement per pig increases too, but the total feed consumption per pig also increases. Feed costs must therefore be taken into account, including the marginal feed efficiency – i.e., how feed efficient is the heavier pig. And most importantly: what does this mean for the total feed consumption in your production?

DanBred’s benchmark on finisher pigs

|

DanBred supports your business: breeding progress for feed efficiency

The breeding work has a big influence on how productivity for the finisher pig-traits develops, and how efficient the animals are, and remain, at different slaughter weights. In the past, there has been a tendency for feed consumption per kg of growth to increase in the latter part of the growth period, as the pigs deposit more fat than protein around the time of slaughter.

This is still the case, but if you look at the last 10 years of breeding progress for feed efficiency in DanBred finisher pigs, we have experienced a significant increase in the efficiency of the herds. The average in Denmark and the best third in Denmark, for 2012-2021, can be seen in Table 1. During this period, feed efficiency improved by 0.21 and 0.17 kg feed/kg gain respectively.

The best third of producers in Denmark have pigs that grow approx. 50 g/day faster than average. They can keep the same meat percentage as the average producer but have a feed consumption per kg growth that is approx. 0.12 kg feed/kg growth lower than the average in 2021.

Table 1: Danish finisher pig results from 2012-2021. National average and average for best third.

Source: Danish pig production’s competitiveness via Time Series 2012-2021 and calculations by Michael Groes Christiansen, Special Consultant in SEGES Innovation.

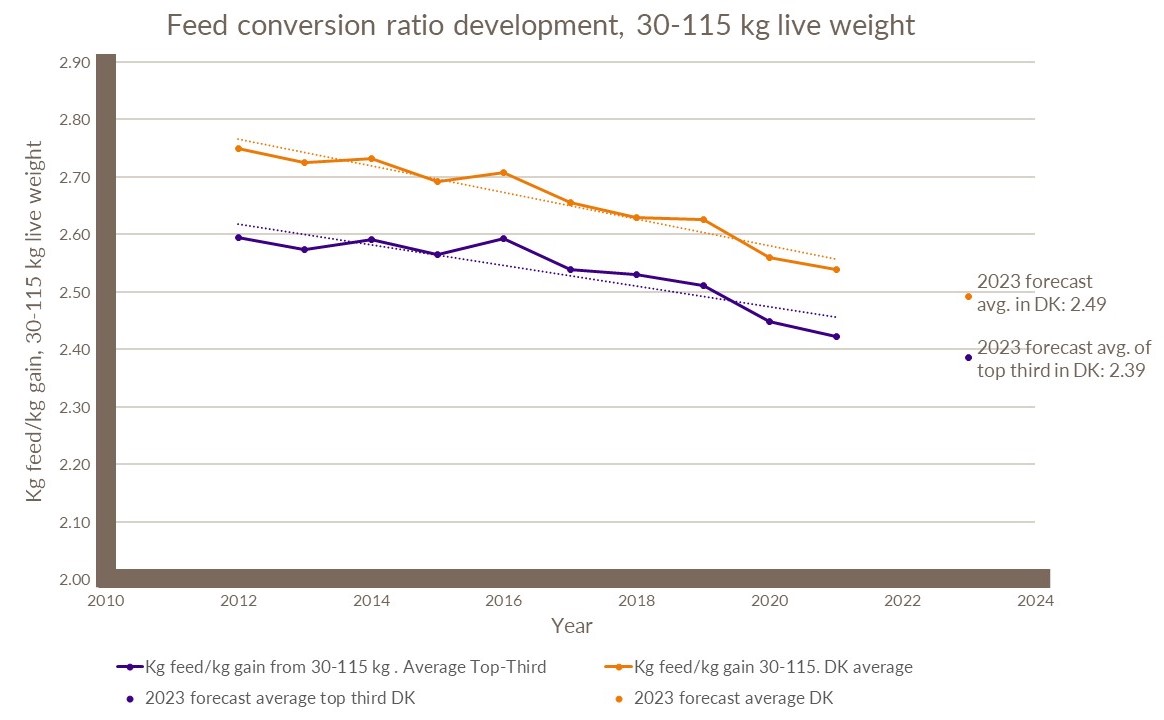

On average, the breeding work ensures an improvement in feed efficiency of approx. 0.02 kg feed/kg gain from 30-115 kg per year. Figure 1 shows a linear development in feed efficiency over the years, which is expected to continue in 2023. In 2023, we expect average producers to need 2.49 kg feed/kg gain from 30-115 kg, while the best third can settle for 2.39 kg feed/kg growth.

Figure 1: Development Feed conversion ratio 30-115 kg live weight in DK 2012-2021 for the average producer + the average for top third producers.

Source: Based on Tabel 1 and calculations by Michael Groes Christiansen, Special Consultant in SEGES Innovation.

Feed efficiency and optimal slaughter weight: how do I find the optimum?

Often, we talk about the average feed consumption. The marginal feed consumption, on the other hand, is something slightly different. It is higher than the average feed consumption, as it depends on the slaughter weight. For 2023, a marginal feed consumption per kg slaughter weight at around 95 kg has been calculated to around 4.21 kg feed/kg carcass for the best third and 4.35 for the average producer, as shown in Table 2.

The feed cost that is used to decide the optimal slaughter weight must take the marginal feed consumption into account, e.g., the cost of going from 94 kg to 95 kg slaughter weight. This means that marginal feed consumption multiplied by the price of feed tells us the reference point for changing the slaughter weight.

Calculation example: Feed cost from 94 kg to 95 kg slaughter weight

0.4×4.21 = 1.6 EUR for feed per kg carcass |

If the settlement price is higher than this, then you achieve a marginal gain by increasing the slaughter weight. If not, then you should consider lowering the slaughter weight, because then the feed cost per kg marginal slaughter weight will be lower. At a slaughter weight of 80 kg, approx. 10 % of the marginal feed cost per kg of marginal carcass gain is cut compared to a slaughter weight of 95 kg.

Table 2: Expected correlation between slaughter weight and marginal feed consumption in kg feed per kg live growth rate or kg feed per kg carcass growth 2023.

Source: Michael Groes Christiansen, Special Consultant at SEGES Innovation.

The conversion factor from slaughter weight to live weight is also important to mention here, as this forms the basis for whether you really do end up at the optimal slaughter weight. Smaller trials in Denmark show that for approx. 18 hours of fasting, a conversion factor of 1.31 from slaughter weight to live weight must be used. But when we look at DanBred D(LY) finisher pigs, who have a high feed intake, it actually means that there is a basis for a higher conversion factor at the last weighing before slaughter.

For DanBred D(LY) pigs fed ad libitum, a conversion factor of 1.33 should be used to estimate the slaughter weight based on live weight. If you want to achieve a slaughter weight of 95 kg, you must multiply by 1.33 to obtain a live weight of 126 kg at the last weighing and a fasting period of 18 hours until slaughter.

The breeding work in DanBred forms the basis for an increased slaughter weight

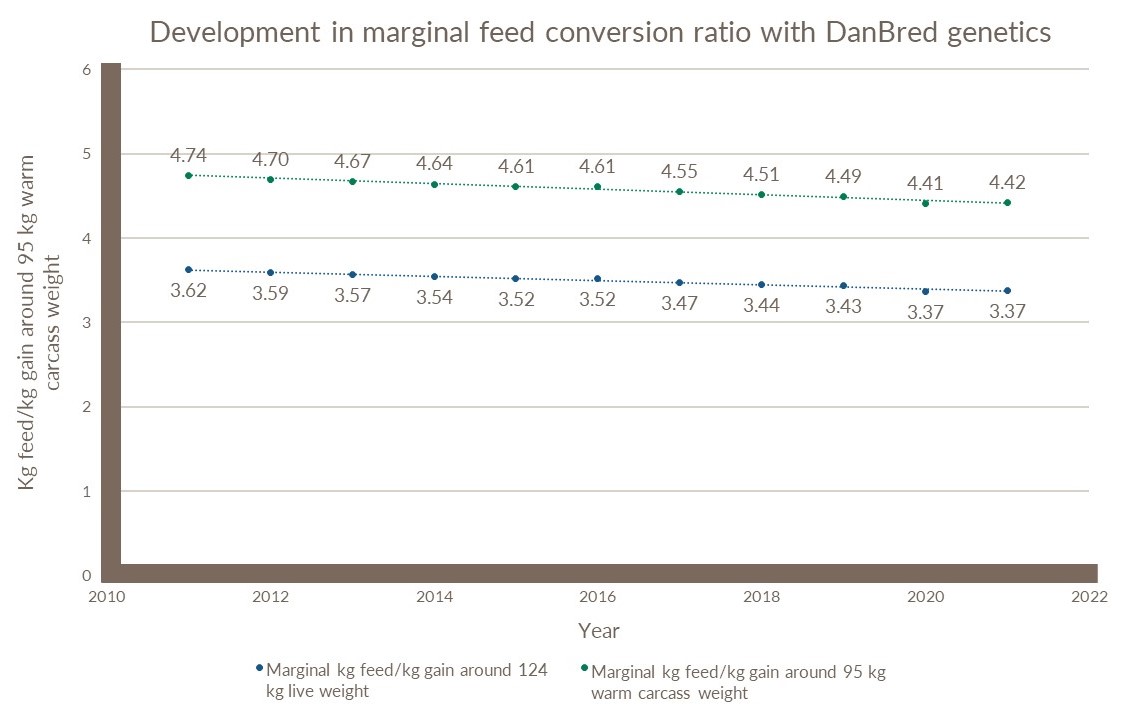

With DanBred’s breeding work and progress for feed efficiency, a basis has been created for a higher and higher slaughter weight. It is less costly to feed the pigs in the latter part of the growing period, as it simply requires a smaller amount of feed.

Figure 2: Development in marginal feed consumption per kg growth with DanBred genetics in Denmark.

Source: Hansen C 2022, National average for productivity in pig production in 2021, and Michael Groes Christiansen, Special Consultant in SEGES Innovation.

This means that the production of DanBred slaughter pigs optimises the bottom line with lower feed consumption, and, thus, lower feed costs throughout the pig’s life, as well as with higher growth, which reduces the number of days until slaughter and improves the overall economy of the finisher pigs.