Results from a nationwide swine farmer and veterinarian Precision livestock farming (PLF) acceptance survey.

U.S. pig farmers continue to contend with challenges amidst rising production costs, labor shortages and shrinking profit margins. These challenges are worsened by the increasing need to modify pig production methods in response to social issues such as legislation, referendums or retailer responses to consumer complaints. Precision Livestock Farming (PLF) tools that provide continuous, automatic, real-time animal monitoring and data collection can address some challenges confronting pig producers. The potential of PLF to transform U.S. pig production is significant. Specifically, PLF can potentially increase productivity on the U.S. swine farm — while contributing to cost reductions, pig productivity, health and welfare, as well as making laborer jobs more accessible and safer.

Currently, PLF uptake has yet to effectively take off on U.S. swine farms. One reason might be that we need to understand critical on-farm user views, like producers and veterinarians. Understanding these perceptions is necessary to understand what PLF is valid, what type of PLF is most wanted and where there could be difficulties with on-farm PLF implementation. Within this study, we assessed U.S. swine farmer and veterinarian awareness, perception and attitude toward PLF.

Study participants

We surveyed swine farmers and veterinarians during annual production meetings across the U.S. Most swine farms and veterinarians are located in Michigan, Iowa and North Carolina. Nearly all of them are commercial swine farms with vast numbers of pigs and many of the veterinarians provide services to livestock producers within and or across different states.

Three-quarters of the swine farmers who participated in the survey were male, with an average age of 45 and 21 or more years of farming experience. The average swine farmer who participated in the study had 9,607 sucking piglets, 39,051 grower or finisher pigs, 15,071 nursery pigs, 1,025 lactating sows, 4,681 gestating sows and 30 boars at the time of the survey. Of those who completed the survey, most identified as farm owners (41%), farm managers (28%) and farm workers (5%). One-third (31%) of those farms are located in Michigan, 10% in Iowa and almost half (49%) in North Carolina.

Half of the veterinarians who participated in the study identified as male, with an average age of 46 and having at least 16 years of veterinary experience. Most of the veterinarians (80%) identified as general practitioners. About 40% of the veterinarians have their office in Iowa, 28% in North Carolina and 2% in Michigan.

Are U.S. swine farmers and veterinarians aware of PLF technologies?

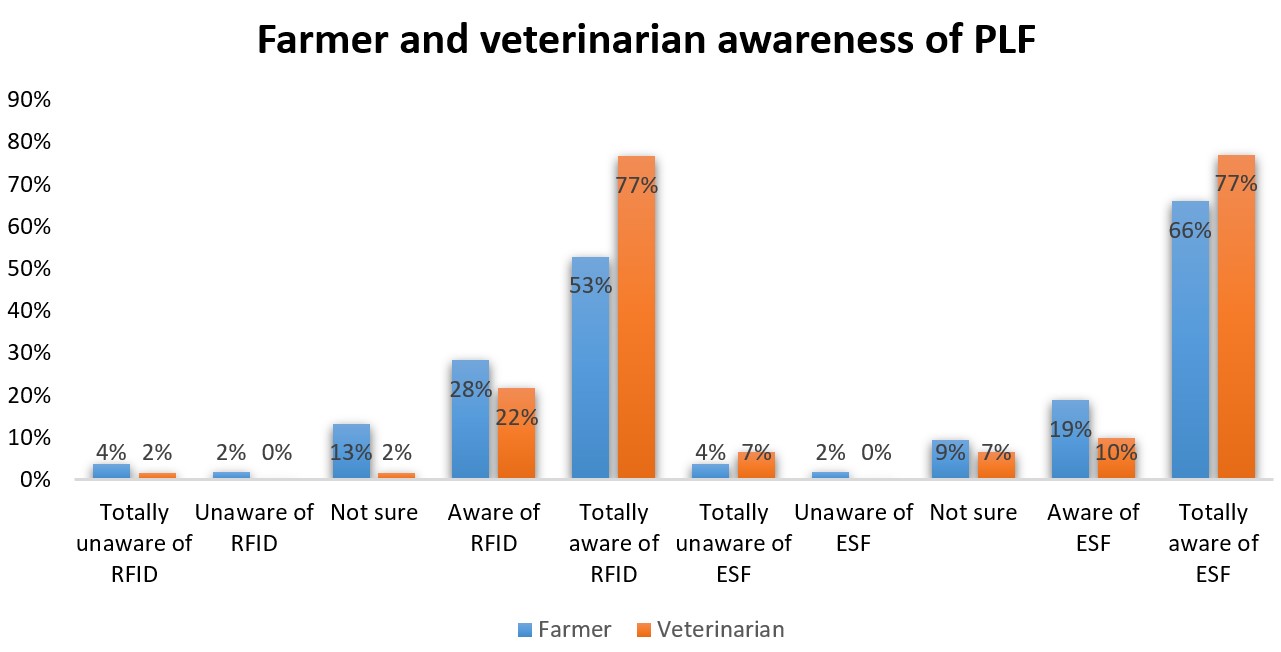

Many swine farmers know Electronic Sow Feeders (ESF) and Radio Frequency Identification (RFID) as the most suitable examples of PLF technologies. Many farmers need to become more familiar with pressure plates for detecting lameness in sow feeding stations and microphone technology for detecting respiratory problems.

Similarly, most veterinarians were very aware of Radio Frequency Identification (RFID) and Electronic Sow Feeders (ESF) but are least aware of pressure plates PLF technology for detecting lameness in sow feeding stations and PLF technology for automated measurement of individual pig water intake. The high awareness of ESF and RFID may be because these two technologies have been used inside swine systems for the past few decades and there are regulatory requirements for their use on U.S. swine farms. In comparison, pressure plates and water drinkers are relatively new and less established on swine farms.

What percentage of U.S. swine farmers use PLF technologies?

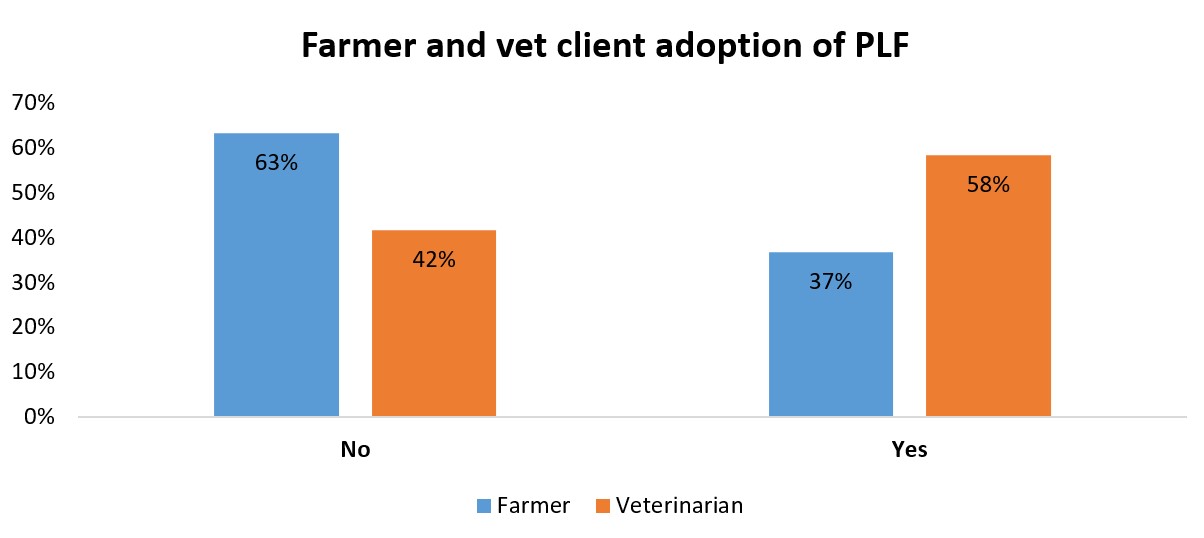

About 37% of the swine farmers have implemented and used PLF on their farms, whereas 63% have never used any PLF technologies in the past or at the time of the survey. Within the 37% of swine farmers who use PLF technologies, most mentioned ESF as their number one PLF technology of choice. Some ranked RFID as their first choice, while very few listed weighing scales, video monitoring cameras and automated data entry tablets as their first choice.

More than half (58%) of the veterinarians said their clients use PLF technologies, whereas 42% said their clients do not use any PLF technology. Veterinarians reported clients using ESF, RFID, weighing scales, cough monitors and barn monitoring cameras. Veterinarians noted that they felt most farmers were satisfied with the PLF technologies on their farms.

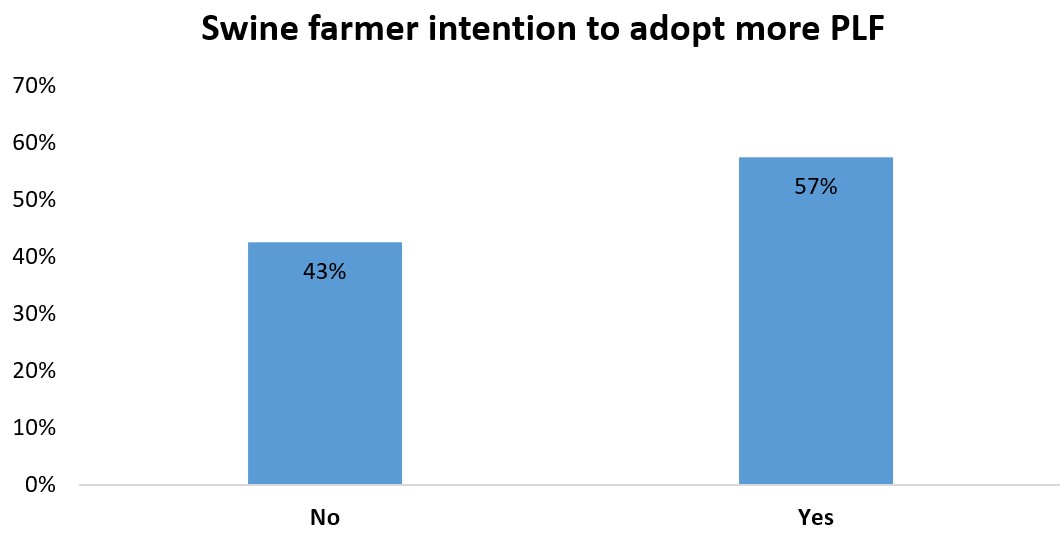

Will U.S. swine farmers use more PLF technologies in the future?

Over half (57%) of the farmers stated they intended to adopt PLF technologies in the future. Among the farmers who have never used PLF, 48% (not shown in the chart) planned to adopt PLF technologies for the first time, but 52% (not shown in the chart) who have never adopted PLF do not intend to adopt PLF technologies. Interestingly, 87% (not shown in the chart) of the farmers who used PLF technologies intended to adopt more PLF technologies in the future.

Some specific PLF technologies that farmers intend to adopt in the future include electronic sow feeders, microphone cough monitors, heat detection technology, weighing scales and pressure plates/mats for detecting lameness. Most farmers felt these technologies had potential value on U.S. swine farms. Others said they were open to considering many technologies or were wondering which they would use on their farm first. Farmers already using some PLF technologies tend to say they plan to adopt more PLF in the future, while those without PLF indicated they plan to keep it that way.

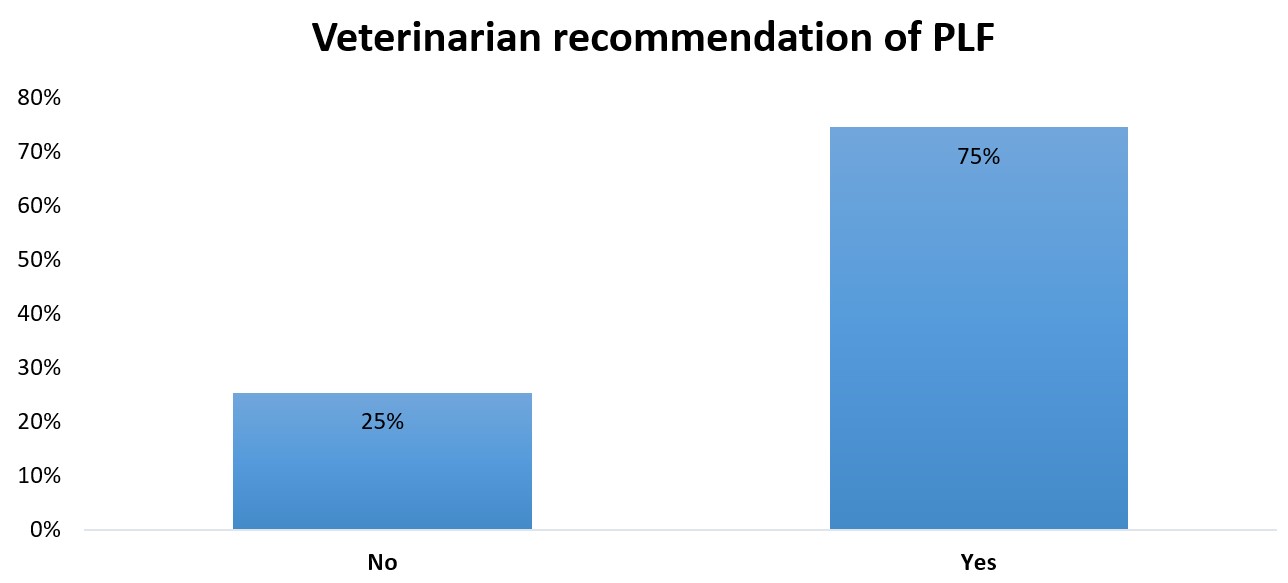

Will U.S. veterinarians recommend PLF adoption to their clients?

Most veterinarians (75%) indicated they would recommend PLF to their producer clients. Veterinarians thought PLF would be most helpful to producers if it could assist with providing information about feed and water intake, weight, animal identification and health and well-being. Many veterinarians recommended PLFs that monitored pig health and welfare, such as cough monitors, lameness sensors, anti-piglet crushing tools and body condition scoring technology. Some said they would recommend automated feeding technologies such as ESF and sensors for monitoring water intake. Those who recommended PLF for pig monitoring and identification mentioned RFID, cameras and pig counters.

This study assessed the U.S. swine farmer and veterinarian awareness, perception and attitude toward PLF. Most farmers and veterinarians are aware of precision livestock farming technologies such as ESF and RFID used for automatic feeding and individual identification of pigs but need to be made aware of technologies for detecting sow lameness and respiratory problems. Less than half of the farmers use PLF technologies, whereas more than half of veterinarian clients use PLF technologies. Most farmers intend to adopt productivity-enhancing and welfare-enhancing technologies such as electronic sow feeders, heat detection, weighing scales, microphone cough monitors and pressure plates/mats for detecting lameness in the future. Veterinarians affirmed their likelihood of recommending PLF, which could provide information about feed and water intake, weight, animal identification and health and well-being, which they thought would benefit producers.