There’s no question the US swine industry is struggling through a down market cycle. Jason Woodworth, Research Professor at Kansas State University, spoke to attendees at the Annual Four Star Pork Industry Conference held in Muncie, Indiana in September about nutritional strategies for feeding pigs during a down market.

“Unfortunately, the goal may be to lose the least amount of money that you can during this time, and we have to look through that lens at the idea of profitability,” said Dr. Woodworth. “Our reality is that we’re going to be on the bottom side of zero, and we’re trying to conserve as much as we can. I’d encourage producers to be as nimble and flexible as possible and to try to take advantage of what’s going on in the market as well as what’s happening in your barns.”

Get the basics right

Taking care of pigs is a producer’s core job, so it’s important to stay focused on feed, water and the environment. Following are suggestions to consider and monitor in your barns:

- Proper feeder and feedline setup uses all the feeder spaces and keeps feed available to the pig. Woodworth says if the feed isn’t getting to the pigs, you’ve got trouble. He shared an example of a five-hole feeder that’s only has feed coming out of two holes.

- Partially filled pens don’t work well with some feeders. The picture identifies an example of a lot of wastage because the pen on the bottom side was

- Adjust the feeders frequently. A properly adjusted feeder can have a big impact on feed wastage and a big impact on feed efficiency from a nursery perspective. Target feed pan coverage is 40% to 50% without feed accumulating in the corners when the pigs are placed into the nursery. The newly weaned piglets aren’t strong enough to work the gates on the feeders. But once you get to the end of finishing, about 20% to 30% of pan coverage is needed to be able to minimize feed wastage and maximize the amount of feed you want consumed by pigs to support the level of growth needed.

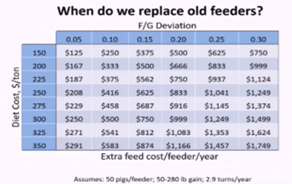

- Is it time to replace old feeders? It’s important to consider what an inefficient feeding system is really costing you. Dr. Woodworth has created a chart that shows the extra feed cost per feeder per year that you may be paying if your feeders are not working well.

- Revisit feeder space and stocking density recommendations. Woodworth shared a feeder management guide and reminded producers to make sure they have the right number of feeder spaces per pig and the right amount of space per pig and that pigs have easy access to the feeders.

- Easy access to water. Oftentimes water is considered the forgotten nutrient. Ensuring clean water is getting to animals to support their growth is essential. He said this summer he was assisting with a farm that had been experiencing poor growth, scours, and sows losing weight for about six months. He said they’d looked at every nutritional reason or disease that may have caused the symptoms that were seen. The problem turned out to be plugged water lines due to extensive corrosion in the pipes. Thus, the water intake on those sows was very limited. They weren’t eating; they weren’t making enough milk; piglets weren’t growing. They cleaned the lines and went through the barns and changed out all the water nipples and practically overnight things changed for the operation. He also reminded producers to make sure that gilts know where to find water nipples and how to get water from them. Being in a farrowing crate is a new experience for gilts and access to water is really important, especially for gilts, so help them find and use the nipples.

- Consider environmental opportunities. Woodworth shared a recent trial of Pillen Family Farms showing the use of detergent prior to power washing. Ultimately, about a three-cent per pen costs in detergent resulted in a reduction of mortality by 1.1%. They attributed this to about 58 cents per pig through their value system, just by spending that three cents per pen to apply the detergent. Especially in down markets, we start looking at ways to cut costs and save every penny we can, but don’t get so ingrained with that mindset. Be open to considering all your options and understand the difference between a cost and an investment that results in additional return.

- Particle size. Woodworth says he can’t stress enough the importance of proper particle size. Producers will see about 1% improvement in feed efficiency for every 100 microns of grain particle size that is reduced. For every 100 microns of higher particle size than the goal, about seven pounds of extra feed per pig is required to achieve the same amount of gain. That means about $1.05 per pig at a $300 feed cost is wasted because the feed is not ground to the target particle size. He recommends routine assessment and monitoring of particle size. The target is to get down to a 500-to-600-micron particle size, and he says that’s about as low as you can go with meal-based diets. Any smaller and you may experience feed flowability issues. However, pellets give you a little more leeway. Getting the right particle size for your pigs will help improve feed efficiency and minimize excess costs.

Set targets based on your goals

Regarding SID lysine for nursery pigs, Dr. Woodworth says to set your diet formulation based on your operational goals. If your goal was a maximum average daily gain, you might formulate to 1.28 SID lysine in Phase 3; if you want to formulate for the best feed efficiency, that target increases to 1.42. If your goal is the lowest feed cost per unit of gain, you want to formulate to 0.85. If you want to maximize income over feed costs, basically a return on investment, you want to formulate to 1.34.

“Especially in down markets, producers want to do everything to control costs, but understand that if you are too cost-focused, you may be losing margin, so you’re actually in a worse position than if you accepted a little bit higher cost,” he said. “Chase the right target for your operation, but make sure your calculations are satisfying whatever business goals you have within your system.”

Reevaluate feed additives

Adding fat to the diet is typically done to increase energy intake, and it replaces corn in the diet. To determine if it’s economically viable, Dr. Woodworth uses a 4:1 ratio of the fat price to corn price as a general rule of thumb. Price relationships that are lower than that ratio indicate that fat is a good buy as a supplier of energy and should be included in diets.

“In the past, it was common to include fat in grow-finish diets,” he said. “But as the fat price has increased and with $4 to $4.50 corn, it doesn’t make economic sense. While everybody wants better feed efficiency, if it’s costing you more money to achieve that improved feed efficiency, it’s not what your banker is looking for right now.”

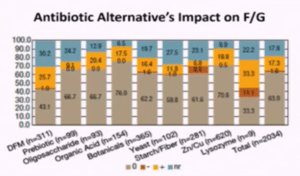

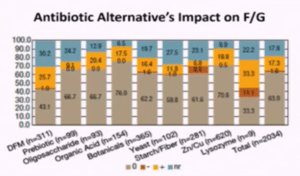

At a time of down markets, it’s important to consider what your feed additives are bringing to your operation. A meta-analysis of about 2,000 research papers was conducted by Iowa State researchers on feed additives that are considered alternatives to antibiotics.

The brown bars

“The reality is that across the board from 7% to about 30% of the trials showed an improvement in feed efficiency from adding the feed additive,” he said. “This is something that we really need to keep in mind – there are opportunities for feed additives to help improve performance, but we need to understand what it’s really doing for us and if we’re capturing that value from an economic standpoint.”

Kansas State followed up with their own trial, focused only on growth of finished pigs. He said about 30% or less of the trials had a statistically significant improvement in feed efficiency from adding the feed additives.

“I want to be clear – I’m not telling you not to feed any feed additives. What I’m telling you is to make sure they bring the value that you expect. There are ways to be able to monitor that by looking at the full data set and/or testing products in some flows,” he explained.

Learning about the microbiome

“There’s a lot of innovation going on in our industry, and there are a lot of things that are cool and shiny that we all like to talk about. Right now, the microbiome is one of them,” he said. “We’re really at the front side of learning about it. When you start thinking about the microbiome, it’s all the bacteria that are in the gut. They have metabolic benefits for us; they help from a protective standpoint; they have direct influences on the immune system. Anywhere from 10 to 100 trillion different bacteria are in your gut right now.”

There is much still to learn about this very complex system. And it’s an area that’s garnered a lot of research. Dr. Woodworth said it’s not an area to ignore, but we need to better understand the microbiome and the impact it can have on overall growth performance before investing it in.

“There’s a lot of talk going on, and some of these products marketed to improve the microbiome are relatively expensive, and we don’t really know about the full outcome,” he said. “Make sure you’re getting performance benefits out of any products that you’re adding to the herd’s diets.”

Operational excellence

“Ultimately, it’s the focus on operational excellence that’s critical to your business, especially during a down market. This is from the top to the bottom – controlling costs and making sure you’re maximizing margin as much as you can. Unfortunately, in a down market that margin means losing the least amount of money in your system,” he said. “But a lot of it comes back to what we can control, and that takes us back to what’s happening in the barns, what’s happening in the feed formulations, and it goes back to working with your people and making sure everyone is doing their best to take care of the pigs as the top priority and reduce wastage whenever we can.”