Water is the most important nutrient for any animal. Yet, it is also the nutrient that is often overlooked the most. Most farms invest heavily in optimizing the feed for their animals together with their feed supplier. Animals need to drink sufficient, clear, and healthy water to reach low feed conversion rates. The good news is that water is also the only nutrient that is fully in control of the farmers and can be improved easily. So how do you make water great again?

Check the water quality at the source and at the end of the line.

- Sediment: Are there particles floating in the water?

- Clear: Is the water transparent or is it cloudy?

- Colour: Put water in a white bucket, is the water visibly discoloured?

- Odour: Does the water smell?

Did you confirm any of the above points? If so, there is room for improvement. If the water quality is good at the source, but problems arise at the end of the pipeline, then the water is getting contaminated inside the distribution system.

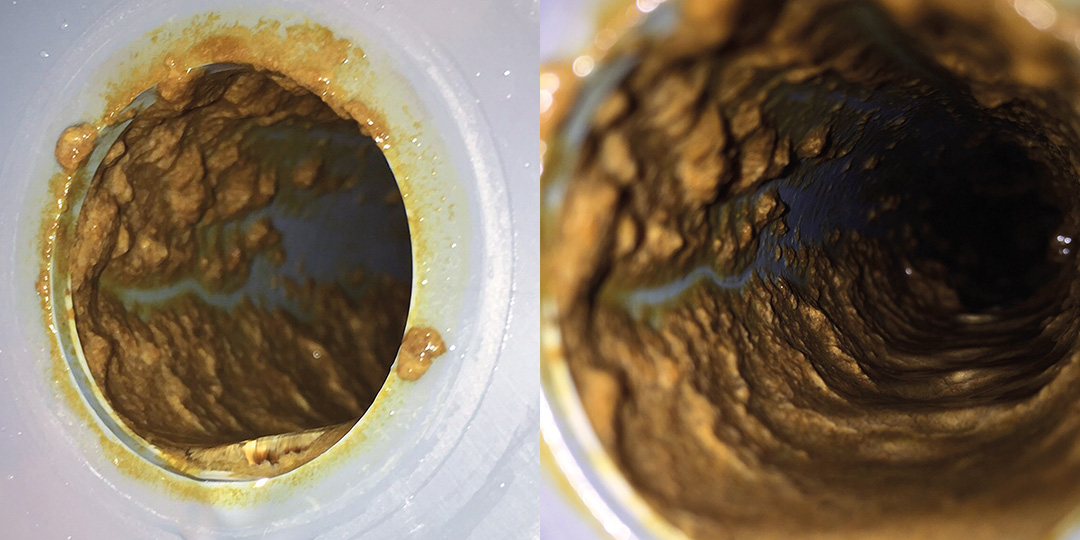

Prevent and remove biofilm in the pipelines

Drinking water systems are often used to distribute feed supplements or medicines to animals. Even when the water source is of high quality when it enters the farm, the leftover additives that remain in pipelines are a breeding ground for bacteria. Biofilm in the pipelines forms when these microorganisms start to grow on the buildup of minerals and organic material that remain on the pipe wall. The bacteria produce a mucus layer that grows bigger over time which protects the bacteria hiding behind it from disinfectants.

Biofilm is divided into 2 layers: a soft out layer, and a hard inner layer. Over time, the pipes become clogged with the biofilm and become a source of pathogens, bacteria, spores, and viruses (e.g. E.coli, Salmonella, Clostridium, streptococci, staphylococci, Campylobacter, etc.).

Select the right disinfectant

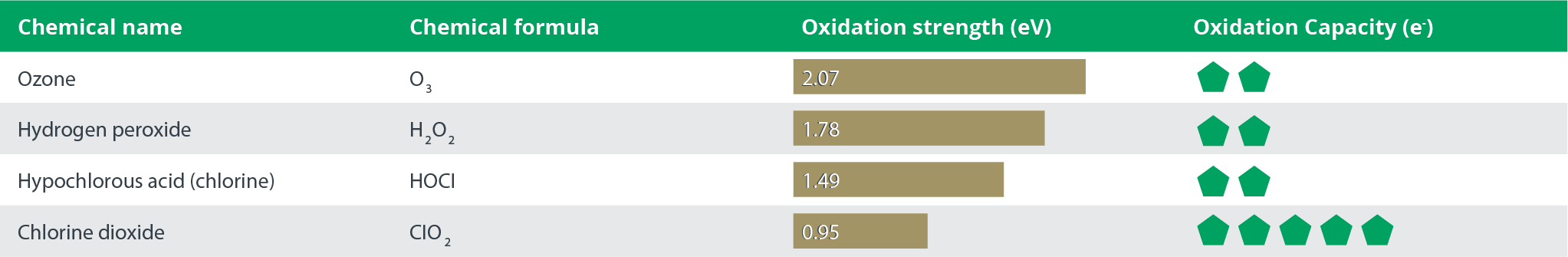

Disinfectants that can remove the biofilm from pipelines have different chemical compositions. The four most used chemicals are; Ozone, Hydrogen Peroxide, Chlorine, and Chlorine Dioxide. Two important characteristics that determine the effectiveness of these disinfectants are oxidation strength and oxidation capacity.

Oxidation strength

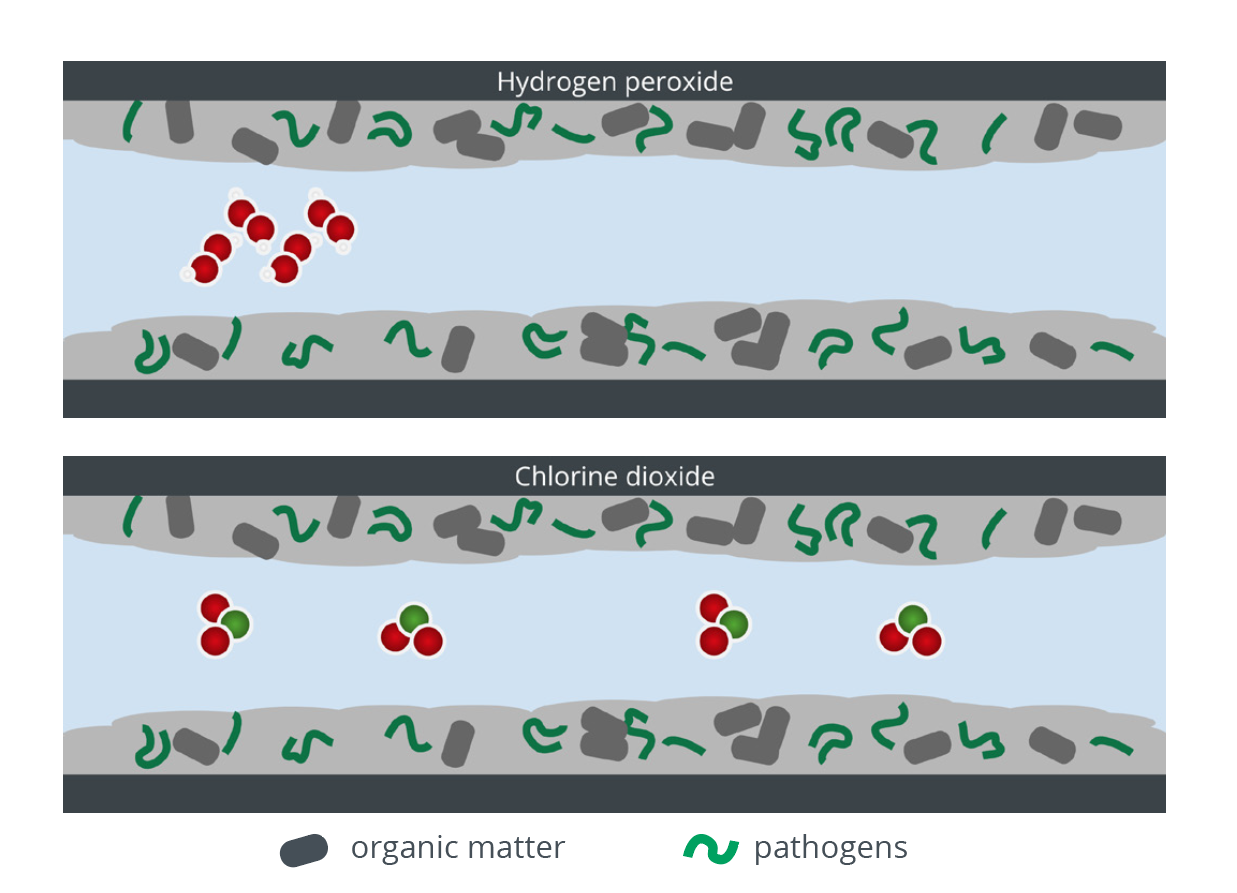

The higher the oxidation strength, the stronger the oxidative power of the disinfectant. This means it will react with any matter that can be oxidized. A lower oxidation strength means that the disinfectant will react more selectively. It will react with pathogens but not with general organic matter present (see example in the figure on the right: top: H2O2 reacts with organic matter and pathogens, bottom: CIO2 reacts with pathogens only).

Oxidation capacity

The oxidation capacity tells how many times one disinfectant molecule can oxidize another compound.

Most disinfectants can react two times (for example, H2O2 in the top figure on the right), Only chlorine dioxide can react five times. Chlorine dioxide is as such the only component that remains effective in low concentrations (bottom figure on the right).

Chlorine dioxide has a high oxidative capacity

Chlorine dioxide effectively penetrates the protective layer of biofilm without being used up in reacting with the inert sugars in the mucus. This allows the CIO2 to act directly on the bacteria themselves, destroying the source of the biofilm.

Low concentrations are safe for animals

The high oxidation capacity and low reactivity towards the organic matter mean that chlorine dioxide can be dosed in a much lower concentration than chlorine. This in turn ensures the lowest possible intake of chemicals by the animals. Chlorine dioxide can be used continuously to prevent biofilm formation in pipelines, also during the round.

Taste affects the water and feed intake of animals

One of the most important benefits of chlorine dioxide over chlorine is that it does not influence the taste and smell of drinking water. The water intake of animals is not negatively influenced by the use of chlorine dioxide. Animals that drink more perform better than animals that drink less. Taste can play a huge role in the drinking behaviours of animals.

Besides its advantages when dosed at low concentration levels, chlorine dioxide is also the preferred product when it comes to a big range of additional chemical properties. Chlorine dioxide is pH-independent, functions independently from byproducts (such as organic acids), has no effects on the smell and taste of the water, and is also the least corrosive chemical to water systems.

Recommended product to remove and prevent Biofilm formation:

MS Gold – Di-O-Clean

Chlorine dioxide is the main component in Di-O-Clean.

- Removes existing biofilm layers in water pipelines

- Prevents the formation of new biofilm

- Kills pathogens and reduces disease pressure

- Improves water quality resulting in increased feed intake

- No labour, the water flow cleans the drinking lines

- Can be dosed with every dosing pump

- Safe to drink when diluted in water

For more information, or to schedule a consultation, reach out to Schippers Canada at 1-866-995-7771!