Benefits include improved heating zone and less maintenance.

1) Less labor for upkeep.

Most growers have limited time and labor they can devote to maintaining equipment because of crop farming or an off-the-farm job. The math is pretty simple…a typical 200′ long wean-to-finish building requires 20 to 22 brooders vs. five tube heaters. That’s at least 15 fewer burners, switches, and valves that must be maintained. Since tube heaters operate similarly to forced air furnaces, growers are familiar with serving this type of equipment.

Here’s a link to a video on TUBE HEATER MAINTENANCE. It runs through the steps needed for the annual tube heater cleaning and maintenance, along with how the burner system operates. Although shot in a chicken house, you’ll get the idea.

2) More reliable.

During transition weather, both types of infrared heaters cycle on and off as the outside temperature goes up and down. Because there are more brooders, there is a greater chance one of them may not re-light.

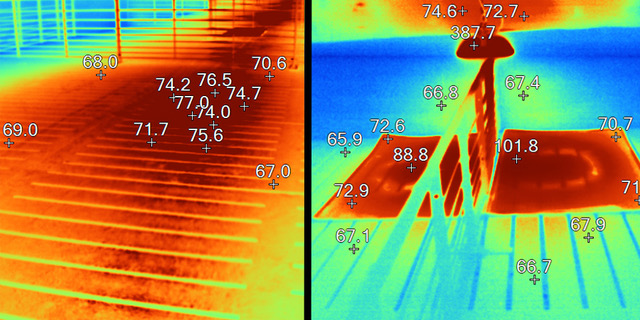

(Thermal images highlighting the difference in heating zones.)

3) Better heating zone

A more evenly distributed comfort zone is the most significant advantage of using tube heat. Thermal photos comparing temperatures of brooders and tube heaters clearly illustrates the difference. The brooders tend to have a hot spot in the middle where the pigs do not lay. An integrator fieldman interviewed about his experience with tube heaters remarked, “The pigs have a much larger “happy zone” with the tube heaters. If we aren’t careful, the pigs will move off the hot spot under the brooders and lay on the slats. In extreme cases, they will even start to dung under the brooders. We don’t even use mats under the tube heaters for the pigs to lay on. The only mats we use are for starter feed.”

4) Some additional thoughts.

Should you choose one or two-stage models? A company rep contacted for this article stated a preference for single-stage models. He said, “The two-stage uses more gas because the low fire can continually run and never quite get warm enough to cut off, all the while maintaining room temperature sufficiently, so it doesn’t get cool enough for the high fire to come on either. Cycling the heater off and on at full power uses less fuel.”

Mount tubes at least 79 inches above a plastic floor to prevent the weakening of the plastic directly under the heater. Mounting distance from the ceiling will depend on the ceiling material. The heaters can be mounted as close as six inches with steel or aluminum ceilings. With PVC liners a strip of aluminum panel installed above the shield helps prevent warpage.

Another observation from the integrator fieldman concerned the “wear and tear” on brooders, “After the pigs get big enough, the growers move the brooders out to storage or another building. They get banged against the gates on the way out and piled in a truck or corner somewhere. They should also bag the brooders to keep them clean if they hang them inside the room. Compare that to tube heaters permanently mounted up out of the way. Less labor and less damage from handling the heaters.”

For additional reading, click on an earlier Hog Slat article titled TUBE HEATERS FOR WEANED PIGS.