Using heat lamps, heat mats, and brooders for localized heating can improve energy efficiency in swine housing. Learn about small adjustments and management considerations for implementing localized heating.

![]()

Providing a thermally comfortable environment for pigs while conserving energy can be a complex problem. For instance, farrowing rooms have animals with very different thermal needs in close proximity. Newborn pigs are most comfortable at a temperature of 86-95°F, however sows would experience significant heat stress at that temperature and prefer temperatures closer to 60-70°F.

To address this, a microclimate is created for the piglets using some type of radiant heater, either an electric heat lamp or a propane brooder, or floor heating, such as an electric heat mat. The heater creates a warm surface so that the piglets can remain in a room with a cool air temperature, best suited for the sow, but still feel comfortable. Piglets can then freely choose the environment that is most suitable for them by either staying close to the heat source or moving away from it.

Heat mats

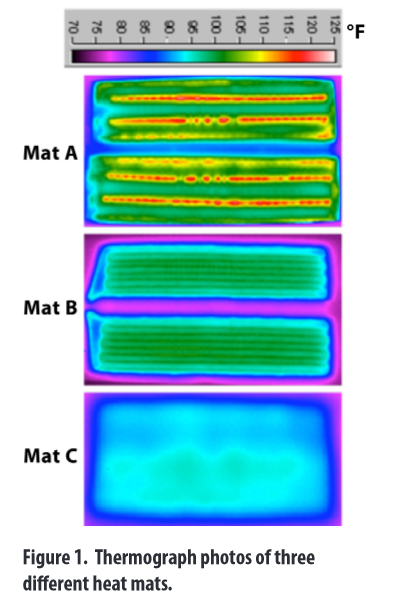

One common tool to provide a microclimate is a heat mat. Mats have electrical resistance coils which create a warm and comfortable surface for piglets. Mats are generally provided in the creep area of the farrowing crate with one double-mat being used for two adjacent crates. Mats generally have lower wattage (60 –100 W per crate) than heat lamps, and are potentially more energy efficient.

Figure 1 shows thermographs (surface temperature distribution) for three different mats. The top mat illustrates red and yellow “hot spots” from the heating elements. These hot spots will drive the piglets off the mat, thus greatly reducing the effectiveness of the heat source. The green areas of the middle mat are also excessively hot, but the bottom mat is more evenly heated and therefore better suited to accommodate an entire litter of pigs.

Heat mats can be controlled much like heat lamps, with reduced heat output as pigs grow larger and their thermal needs decrease. With an increased litter size, a larger mat size of 1 x 5 ft (vs. 1 x 4 ft) per crate should be considered to ensure adequate heated space for the litter before 3-5 days of age.

Heat lamps

Heat lamps are often used to provide a microclimate for piglets in farrowing barns. A study at Iowa State University comparing 175 W and 250 W heat lamps found that the smaller wattage lamps saved approximately 360 kWh per crate ($36 at $0.10/ kWh) in one year. The study also found that pigs gain weight slightly faster with the smaller lamp, had 45% lower lamp breakage rate and there was a 19% lower mortality rate as compared to the 250 W lamps.

Management of the environment below the lamp is important to piglet comfort. Floor temperature below the lamp should be 95-100°F for newborn pigs . If the area beneath the lamp is too hot, piglets will move away from it. Because piglets would then spend more time in close proximity to the sow, they tend to be injured or laid on more frequently. This reinforces why proper lamp adjustment is important.

Piglets need less localized supplemental heat and their temperature preference decreases as they grow. Another ISU study examined constant 175 W lamps versus variable output lamps. When less heat is needed, reducing lamp output saves energy and still provides the proper environment. In the research trial, 175 W lamps were operated by reducing lamp output approximately 2% per day . This reduced electrical power use by 20% compared to constant output lamps. These energy savings cannot be achieved by simply using a rheostat. Rheostats “chop” the output voltage and give off the unused power as heat, but the input voltage or power remains the same. Instead, a controller such as a triac or a device which varies the electrical frequency is required.

The fine-tuning of the lamp output can be accomplished by observing the piglets. The figure below shows how the seven-day-old piglets on the left seem too warm directly under the 250 W lamp and congregate to the sides while the pigs on the right appear comfortable under the 175 W lamp. Observing pig behavior is the best way to evaluate proper settings.

Propane gas brooders

Propane gas brooders are also an option in farrowing houses. Most often found in wean-to-finish build-ings, they save energy by keeping the room temperature low, normally in the 70 to 75°F range, while still providing a warmer microclimate to piglets. These brooders work by using propane to create a hot surface which radiates heat to pigs much like heat lamps do. Most of these systems have control valves which allow the output to be adjusted by changing the line pressure.

Excessive energy use with gas brooders can be caused by its size and ventilation settings. When sizing brooders, keep in mind that they are rated by the maximum output in BTU/hr. Oversized brooders may operate at a very low level which may not be as efficient as at high level of operation. The lowest level may also not be as low as needed. When adjusting ventilation settings, the objective of using brooders is to keep the room temperature lower to save energy. However, if the room temperature rises due to pig activity or weather conditions, the ventilation rate may increase to maintain a cooler temperature, thereby causing the brooders to operate longer. One way to avoid this is to program the ventilation rate to increase at a temperature which is higher than the setpoint, but set the space heaters in the room to start at a temperature just below the desired room temperature.

For instance, if the target temperature for young pigs is 86°F, then with brooders the desired room temperature is 72°F. If the controller setpoint was programmed to be 72°F, then ventilation will increase above 72°F. Increasing ventilation to maintain 72°F when we actually desire a temperature of 86° for the pigs is not prudent. A better approach would be to make the setpoint for increasing ventilation rate to be 86°F, but have the room space heater come on at 71°F and off at 72°F. The room temperature may rise above 72°F, perhaps creeping up to 76° or even 80°F at times, but the changes will be gradual and will conserve energy while still providing a good environment for the pigs.

SPECIAL NOTE:Propane brooders require regular cleaning of fil-ters to provide efficient operation. Clogged filters will cause the production of carbon monoxide.

Summary

There are benefits to proper usage of heat mats, heat lamps, and gas brooders for efficient production as well as for energy efficiency. Small adjustments and management decisions have an impact on both of these. Before purchasing heat lamps, heat mats or variable output controllers, check with your electrical provider for rebate opportunities.