Overheating is the leading cause of electric motor failure.

In Part 1, we discussed the basics of how a motor operates and what happens inside a motor when it burns out. Frequently just replacing the motor does not alleviate the problem; finding the root cause of the motor’s failure is necessary to prevent it from reoccurring.

Overheating is the most common cause of motor failure. Overheating damages the insulation protecting the motor windings allowing it to “short out.” A 20-degree temperature increase beyond the rated temperature rise can reduce the insulation’s effectiveness by 50%. Here are several ways to reduce overheating and increase motor life.

1) Start by noting the nameplate on the existing motor showing the horsepower, rpm, voltage, hertz, phase, and frame size to select a suitable replacement. Take a photo of the nameplate and provide this to your motor supplier.

2) Choose motors with a high Service Factor or S.F. The Service Factor shown on the motor plate represents the motor’s ability to operate under a load that exceeds the rated H.P. of the motor. Generally, the higher the S.F., the more resistant to overheating and the more durable the engine.

(Incorrect wiring caused heat buildup melding the wire nuts.)

3) During installation, a motor may have been wired incorrectly. A misplaced wire on a dual-voltage motor allows it to run correctly a first, but it will fail prematurely. Loose spade connections cause low voltage increasing motor temperatures. Consider changing the old spade connections when replacing a motor.

4) When remodeling a facility, the fan sizes often increase along with the horsepower requirements. Drawing more current over a long wiring circuit causes a voltage drop. When excessive, this can lead to overheating. When adding fans or replacing fans with higher capacity units, one should take the time to evaluate the wiring that feeds those fans. Increasing the wire size is often necessary when adding fans to existing facilities.

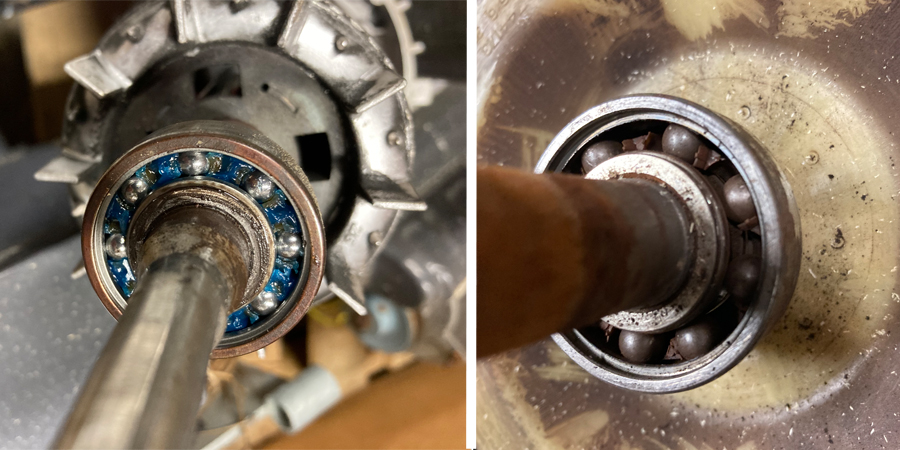

(Extreme temperatures melted grease and damaged ball bearings.

5) Loose fan belts can cause excessive slippage over the motor pulley, causing its temperature to climb over 200 degrees. The motor shaft then transfers this excess heat to the interior of the motor. This transfer may cause nuisance tripping of the thermal protector and, in some cases, failure of the motor’s bearings. Check and maintain correct belt tension throughout the season to prevent this from occurring.

(Excessive high temperatures caused insulation varnish to melt from windings and pool in the motor bottom.)

6) The wrong size pulleys can quickly overheat a motor. While this can happen as an honest mistake, the pulleys are sometimes deliberately oversized in an erroneous attempt to increase fan performance. Increasing the pulley size even slightly causes the motor to become overloaded. Only use pulleys matching the original fan specs when replacing worn parts.

When changing any motor, it is a best practice to check the operating voltage and amp draw. An electrician or qualified service tech can take measurements at the motor to verify. They then can take corrective action if the amps exceed or the voltage is below the listed motor label.

This type of troubleshooting was recently illustrated on a farm experiencing reoccurring failures with a 36-inch fan motor. The voltage reading at the motor only registered 170 volts causing the fan to run slow and never reach full speed. In this instance, the motor was wired correctly with tight fasteners. Tracing the wiring back to the controller revealed a loose wire connection in a junction box. After securing the wire nuts, the motor received the full 220 volts needed to operate correctly.