It’s in the details

Designing a Free Access Stall is different from almost any other equipment built for pigs because it moves. Yes, we have gates that swing and feeders with paddles or levers, but it’s not the same. The internal trigger gate and the rear gate must move smoothly without binding and do it continuously for years.

Hog Slat began the process of developing FAS over seven years ago by visiting existing producers across Europe. After studying where FAS failed and succeeded, we produced our first prototype for testing in Germany and North Carolina farms. The finished product you see now is our 5th version. Getting there required a lot of work.

Balance

Hog Slat engineers used a computer simulation to locate the exact location of the hinge point for the correct balance between the gates. This simulation allowed for testing different rear gates, trigger gates, widths, and stall length configurations.

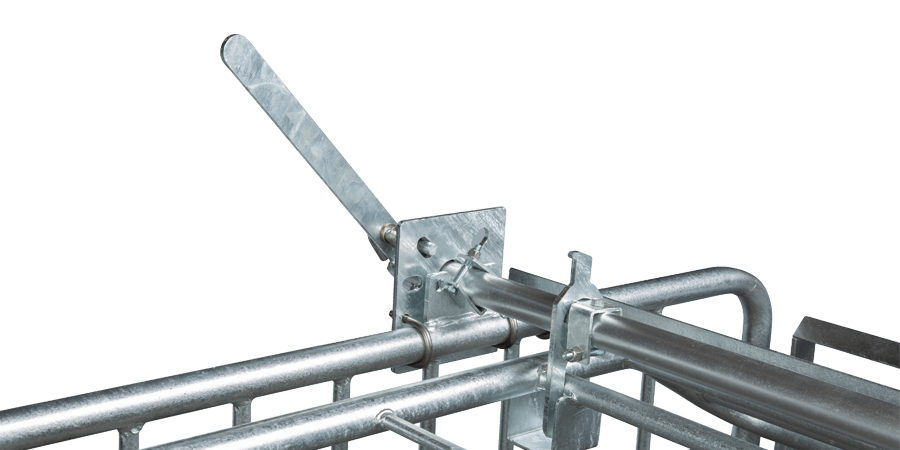

(Rugged, fixed pivot point with stainless steel bushing.)

Hinge Point

For long-term durability, the hinge point must be stable without any “play” and stay that way. Hog Slat’s hinge points are large steel bushings welded in the moving doors. They rotate on stainless steel inserts fixed tightly against the stall side. The hinge point passed a longevity test of 300,000 automated activation cycles representing 40 years of on-farm use. This hinge and the balance are the most significant differences between Hog Slat’s stall and others on the market. Less robust hinges will loosen over time and prevent the smooth operation of the gates.

Lineage

The connection between the rear gate and the front gate must not have any flex. Hog Slat uses a single tube for the linkage with a slight adjustment to set the gate balance. The single linkage rod also gives an AI tech more room when breeding. To test the linkage, we locked the gates shut and repeatedly slammed 500 pounds of force against it, checking for bending and cracking.

(Stainless steel legs rotate 360°)

Adjustable legs

Hog Slat’s stainless steel legs fit inside a stainless steel stall sleeve, making them independently adjustable for height. This height adjustment is critical on uneven floors as smooth operation of the stall depends on installing the stalls level. The legs also rotate 360° to enable secure fastening to the slats or floors.

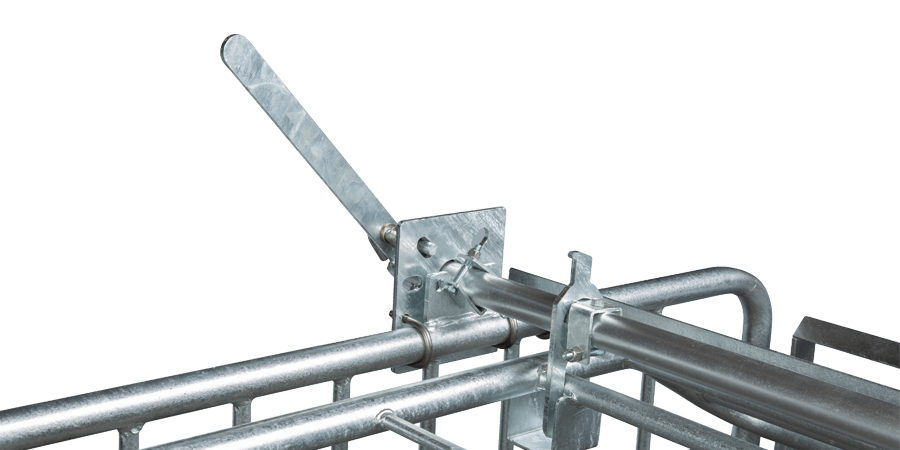

(Robust locking system will lock up to 25 stalls with a single lever.)

Locking lever

A vital management feature of FAS stalls is the ability to lock a row of sows in place. Hog Slat’s robust locking system will lock up to 25 stalls with a single lever smoothly without binding. There are also provisions for locking individual sows in for special treatment.

Tubular construction

Stability is an absolute must for the proper operation of Free Access Stalls. Solid rods do not have the same rigidity as a tube and will flex slightly as the gates activate, causing a slight amount of binding.

Standard 24-inch width

Changing the width means changing the gate weight, which changes the system’s balance. The standard 24-inch width allows ample room for breeding while fitting into most pen configurations.

Making the facility changes for Prop 12 and other welfare regulations requires a substantial capital investment. Along with supplying your operation with a proven product, Hog Slat also provides expertise in equipment layout for new construction or remodeling projects. Several installations have included incorporating Free Access Stalls between ESF feeding stations or integrating them into stanchion systems for individual sow treatment. CLICK to learn more.