This article was written by the AB Vista technical service team of Dr. Caitlin Evans, Technical Support Services Manager; Dr. Laura Merriman and Dr. Spenser Becker, Swine Technical Services; and Dr. Peter Wilcock, Regional Director – North America

Feed cost represents 70 to 80 percent of the total cost of producing swine today. Thus, maximizing the value of raw ingredients and finished feed is a real concern of producers. Grain particle size is one area of high impact, as corn is a major component that provides energy in swine diets and its particle size directly affects diet uniformity and feed efficiency.

Feed Manufacturing

Whole corn typically undergoes particle size reduction via roller- or hammer mill-grinding. The grinding process is a major expense that can be influenced by the target micron size, where the cost increases as particle size decreases. Whole corn, however, must be ground to help support a homogenous feed and minimize segregation of dietary components during manufacturing, transportation or storage. Changes such as particle shape, size and density will all impact its ability to properly mix and also affect flowability. Poorer flowability is often associated with reducing particle size and can lead to bin-bridging and out-of-feed events on the farm. Pelleting diets can help resolve some of this concern; however, when feeding meal diets, it is recommended that the corn particle size exceed a minimum of 500 microns to avoid handling issues (Goodband, 1995).

Reducing corn particle size may offer some benefit to the pelleting process. The increased surface area of smaller particles favors heat and moisture uptake during conditioning and also allows for greater contact between particles, yielding enhanced binding capacity. It is estimated that a 1% change in feed efficiency will be observed for every 10% change in pellet fines. When considering this response, however, it is important to remember that the pelleting process is dynamic and influenced by many additional factors, which can alter the extent of particle size’s effect on pellet quality in various systems. Thus, for systems already achieving adequate pellet quality, a further reduction in particle size may provide no additional benefit, while other systems struggling to meet quality standards may be able to recoup value based on this principle.

Formulation Strategies

When the particle size of corn is reduced, pigs are better able to utilize the nutrients because there is greater available surface area for the digestive enzymes to interact. This results in increased starch digestibility and subsequent improvement in metabolizable energy. Consequently, in practice, this can alter the amount of energy required from other ingredients within the diet and reducing fat levels may be considered. Alternatively, the nutritionist can choose to hold corn ME constant in formulation, and in this scenario, an improvement in FCR would be observed for corn with a smaller particle size. Reducing particle size does not, however, appear to change the digestibility of minerals or amino acids.

Animal Performance

Typically, the corn particle size recommended for nursery-phase pigs is 500 to 600 microns in meal diets or 400 microns in pelleted diets. Nursery pigs appear to have heightened sensitivity to palatability when corn particle size drops below 500 microns in meal diets, resulting in depressed feed intake and little change to feed efficiency. When corn particle size exceeds 600 microns, nutrient digestibility suffers.

In finishing pigs, minor improvements in feed utilization can translate to significant economic gain due to the increased feed volume consumed. Research has demonstrated that typically for every 100-micron reduction in grain particle size, down to 300 microns, swine feed efficiency is improved by ~1% (Wondra et al., 1995 and DeJong et al., 2012). Although there are performance benefits of reducing particle size, these can be offset by flowability issues occurring below 500 microns and a potential higher incidence of gastric ulcers occurring below 300 to 400 microns. Thus, the typical corn particle size recommended for finisher pigs is 500 to 600 microns in meal diets. There appears to be little benefit to reducing corn particle size below 600 microns in high-quality pelleted diets (Nemechek et al., 2014).

Measuring Particle Size

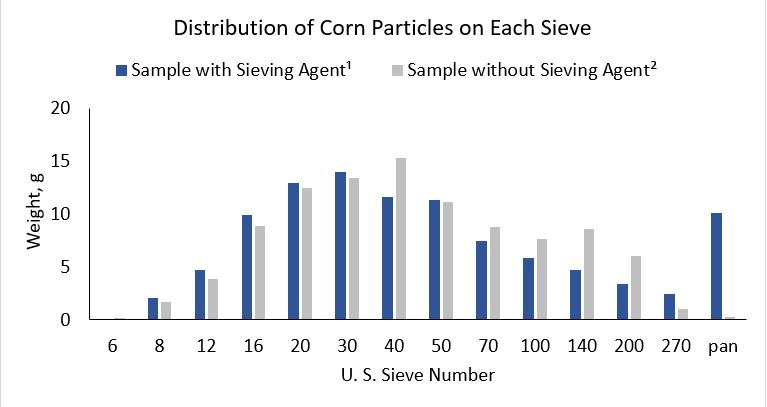

The particle size of ground corn performs a critical role in determining swine feed efficiency. Therefore, the producer should also focus on particle size evaluation, as the testing methodology can influence the results. Traditionally, measuring the particle size of ground corn revolves around dry sieving. The standard method prescribed by the American Society of Agricultural and Biological Engineers (ASABE) involves measuring the distribution of a 100-gram sample across 13 stacked sieves of decreasing opening size. The method allows for several variations including the use of sieve agitators, inclusion of dispersing agent and sieving time. Of most significance is whether dispersing agent is included. Figure 1 illustrates how the addition of sieving agent shifts the measured particle size distribution, resulting in greater standard deviation with an estimated 80-micron reduction in particle size. While the lower particle size indicates a more accurate method and is preferred, many producers still choose to exclude dispersing agent. Thus, it is important to note what methodology the results are based on.

Figure 1. Kalivoda et al., 2015

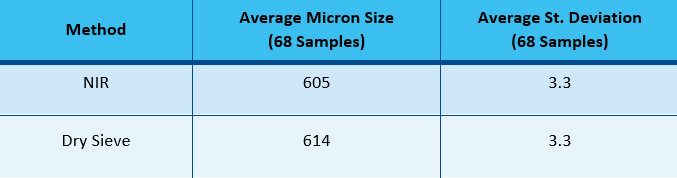

Other variations on the ASABE dry sieve method have been developed and aim to reduce the time and effort associated with the analysis by decreasing the number of sieves, time, etc. Unfortunately, these alterations often compromise the accuracy relative to the original method. Near infrared reflectance spectroscopy represents an alternative and efficient option to measure corn particle size. Table 1 shows the results when 68 ground corn samples were analyzed using the NIR and the ASABE standard sieve method with flow agent and agitators. The data demonstrates that the NIR is able to accurately predict ground corn particle size based on the desired dry sieve method, saving the producer time and allowing for more efficient particle size evaluation.

Table 1. Average of ground corn samples analyzed using NIR and ASABE standard sieve method with flow agent and agitators.

Learn more about AB Vista’s NIR services at https://www.abvista.com/feed-quality-service.